Automation Solutions for the Steel Process Industry

The Steel Industry requires superior monitoring, control, reporting, trending and alarming. Automation we provides for the complete visibility and control, traceability and compliance requirements for your manufacturing processes.

Material tracking systems (GPS, RFID, barcode)

Identification and tracking systems using radio frequency, GPS or barcode techologies. Reliable equipment designed to work in industrial environments. Direct connection to control equipment and / or field networks.

Industrial networks (Ethernet switches, gateways, remote I /O, analysis software)

Field elements that build a robust network

- » Ethernet Switches : Industrial Ethernet Communication critical-mission, data acquisition, and control applications. For rugged environments (up to 75 ° C, vibration, IP67), maximum bandwidth, minimum downtime. For large systems Layer 2 & 3 and managed. Intrinsically safe swithces Class 1 Div2.

- » Gateways : Industrial Protocols Converters that allow interconnectivity between any field device.

- » Remote I/O : Digital and analog I/O modules that simplify sending all signals over a single cable or industrial protocol: Ethernet IP, Modbus, etc. Through copper, fiber optic or wireless.

- » Network Analysis Software : Software for monitoring and auditing industrial Ethernet networks. Displays a graphical interface that automatically identifies the network and problems or intermittent connectivity between computers. Notifies problems and save configurations, increases network security and reduces support costs to them.

Supervisory systems (SCADA / HMI)

Open technology that allows communication with any control equipment, direct connectivity to SAP and databases. 360 ° operations view in real-time , for monitoring and securely manage, from a single point of control, each part of the process and have multiple remote Web clients.

Weighing systems

Systems designed and built specifically to meet the challenges of the steel industry: maximize the product quality, consistency and safety.

Building automation systems (video surveillance, access control, AC and lighting control)

Intelligent systems that interact with each other, one single intelligent platform for supervision, operation and monitoring of systems.

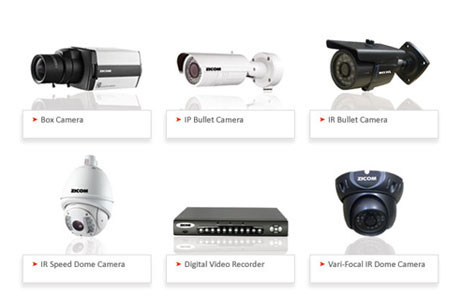

- » Video Surveillance System (IP cameras, communications, storage and management): Intelligent video surveillance system capable of interfacing with process control systems. Robust IP cameras for industrial environments (high temperature, vibration, dust, etc.) Management Software for unlimited number of cameras and multiple remote users.

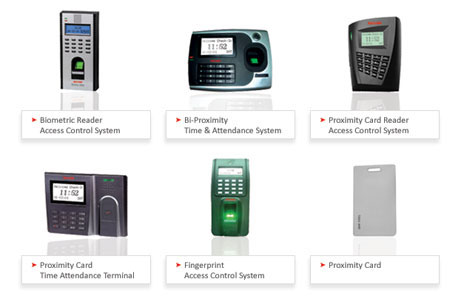

- » Access Control (readers, proximity cards, management): System composed of ID cards, readers and management software for rugged environments, with the ability to link to IP platform plant.

- » AC and lighting control: Equipment thant links, syncs, controls and monitors automatically the HVAC and lighting equipment. Visible & monitoreable by an open platform, via web.

Energy Monitoring Systems

Power meters, CTs, multicircuits, data acquisition systems.

Control devices (cabinets, power supplies, industrial sensors, etc)

High quality equipment, excellent reliability and cost.

- » Cabinets: Standard control cabinets and custom, modular cabinets, consoles, 19 "racks, PC cabinets, network cabinets and distribution cabinets.

- » Automation Devices & Accesories: Power supply DIN rail, disconnects, DIN rail mount enclosure heaters, thermostat, air conditioners, filter fans, receptacles, enclosure lights, mini circuit breakers (MCB), etc.

- » Industrial Sensors: Inductive, ultrasonic, magnetic, capacitive, etc.

Process Control (PLC's, DCS, RTU's)

- » PLC's and DCS: Open system, modular, supports OPC industrial standard; Supports a wide range of I/O points of 10 to 100 I/O; Supports Fieldbus with intelligent I/O modules; Redundat: power supply, communication modules, I/O modules and CPU controller.

- » RTU: Innovative technological equipment that integrates control, communications and interface in one rugged package. Decentralized architecture for monitoring, telemetry, and process control. With options such as integrated wireless radio frequency or cellular network, automatic alarm notifications via SMS or email, integrated WebHMI interface, ready for solar power. Class 1 Div2.

Safety in floor ( External Ports for control panels, voltage indicators, safety light curtains, tower lights)

- » Cabinet Interfaces: safety interfaces/ports for cabinets that reduce the risk of workers. External PLC's ports and other connectors allow workers access to the cabinets without having to open the doors.

- » Voltage Indicators: Checkpoints voltage out of the cabinet.

- » Safety Light Curtains: Flexible and secure.

Portable traffic signal

Designed for harsh environments, solar powered, wireless synchronization and control. Traffic control long-term or emergency for periods of hours or years.